Claw knife type crusher (XMK series)

Project profile

- XMK Claw knife type crusher series wide applicability, mainly used for crushing all kinds of soft and hard pl

service hotline:+86-769-85096969

Detail description

■ The model machine with stainless steel, compact structure, safe and durable;

■ Special claws blade rotor design, making the machine easier when broken material easily;

■ Tool using SKD-11 material production, and the knife after the tool is designed telescopic adjustment, with a blunt blade can grind the blade, durable;

■ Body cooling water system installation, remove the heat generated by the machine at work, avoid crushed material agglomeration.

Suitable for crushing and recyding various injection molding, blow molding edge materials and various plastic parts.

Unique tool design

Machine tool with high strength SKD-11 material, stepped rotor design,the machine in the cutting increased torque, smash the partidles more uniform.

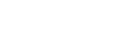

Electrical parts

Using Siemens appliances, star delta start mode, to ensure the safety of the use of the machine.

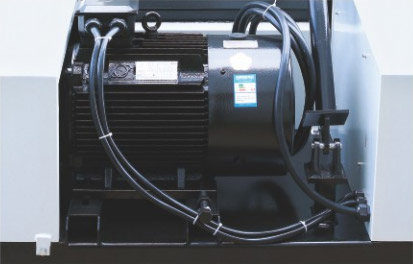

Motor installation

Extermal motor through the U-slot in the fixed, easy to adjust the belt tightness.

| Model | XMK-20C | XMK-30C | |

| Fixed blade knife | 2*1 | 2*2 | |

| Rotating knife | 3*8 | 3*11 | |

| Grinding chamber diameter | mm | 480*340*Φ350 | 660*400*Φ380 |

| Power | kw | 15KW/20HP | 22KW/30HP |

| Rotating speed | 540 | 540 | |

| Crushing ability | mm | 300-400 | 500-800 |

| Sieve aperture | mm | Φ10 | Φ10 |

| Weight | kg | 1050 | 1500 |

| Dimensions | L*W*H mm | 1500*1100*1850 | 1600*1300*1900 |

Keyword:

Next page:Series pipe & profiles crusher (XMP series)

Previous page:First page