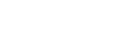

Powerful crusher (XMD series)

Project profile

XMD Powerful crusher series is a new model developed by the company Xiao Ma, the model can not only break the

service hotline:+86-769-85096969

Detail description

■ Built-in enclosures: to ensure that the use noise reduction, and a unique tool designed to make it easier tool change;

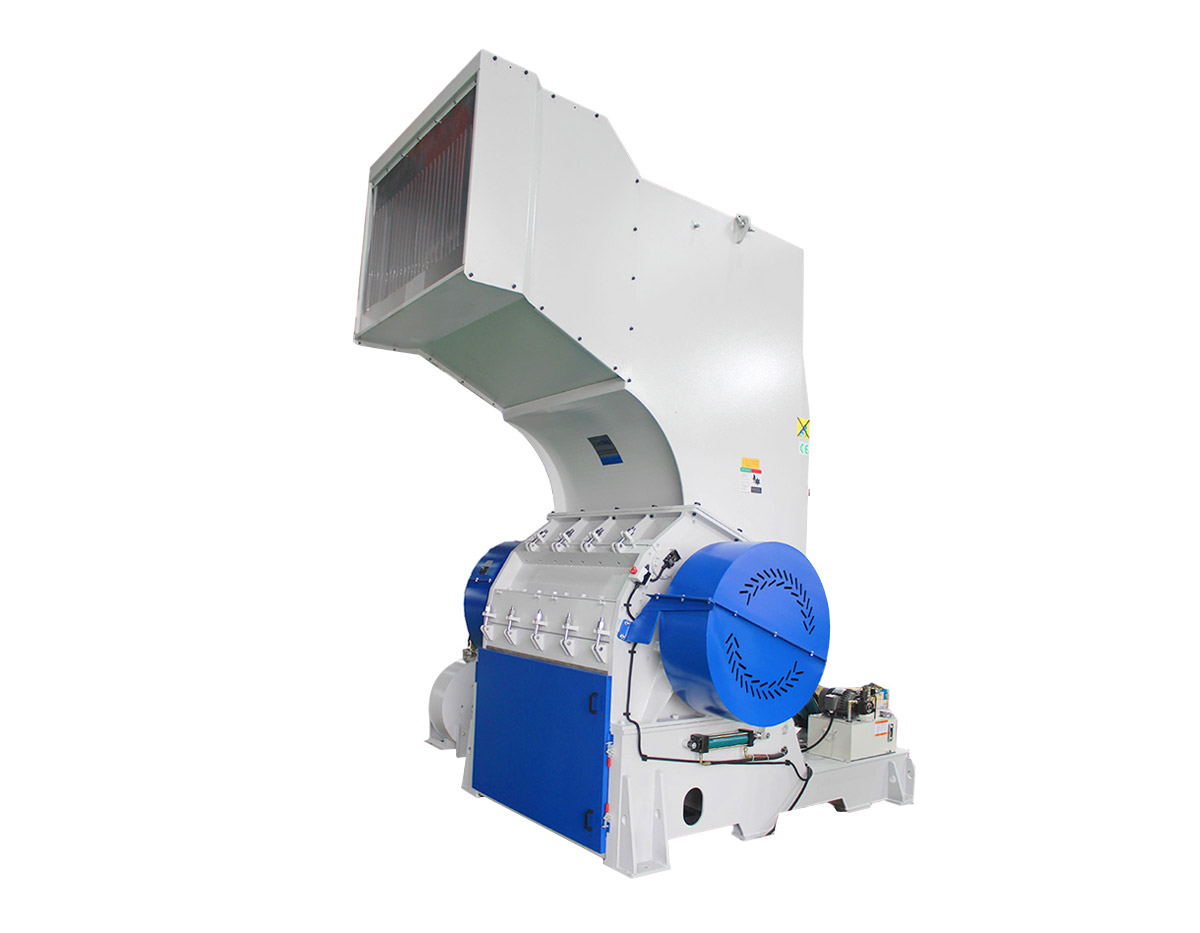

■ Simple tool to install: the adjustments using a tool to adjust the frame, the entire tool change process in the crusher, fixed knife and rotary cutter with high tensile strength stee, regrinding many times;

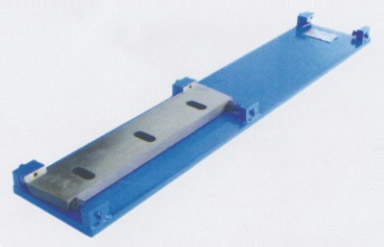

■ The unique cutting mode: the tool of the rotor using the latest "V" shaped cutting technique, compared with the conventional tool, "V"-shaped design materials toward the center of the rotor while continuing cutting, "V"-shaped structure be able to reduce the wear of the tool and crushing chamber.

Bearing installation

Strong bearing device installed on the outside of the machine, and independent crushing chamber to prevent dust and dirt from entering the bearing, not only extend the life of the machine, but also to reduce the maintenance work.

High-alloy D2 or DC53 material, has high strength, good toughness, not easy to break and so on, . at work to ensure a good blade, improve the quality and yield of the broken partidles, and disassembly, repair, and maintenance is very convenient.

Simple tool installation

All knives, indluding knife and static knife can be adjusted in the machine fixture, no longer need to be adjusted after a tough machine tool process. The tool is made from high quality alloy tool steel, can be reground several times.

Economical matching

This is a more traditional way of working. The machine is equipped with a stainless steel four-way receiving box to store the broken material, and then bagged by hand.

Cyclone separation and recovery device

The machine is equipped with a feeding windmill and a cydlone. The bottom of the cydone can directly use the material bag or the ton bag to undertake the crushing material, which can reduce the workload of the manual charging. The air outlet of the cydone can collect a certain amount of dust. In addition, our company also has A dust separation collection system is available.

XMD500/1000 optional combinations

Xiaoma also offers a range of axiliary equipment such as blowers, suction units, conveyor belts, metal detectors and metal separators.

Suitable for crushing and recydling various injection molding, blow molding edge materials and various plastic parts.

| Model | XMD300/300 | XMD300/600 | XMD300/800 | XMD400/600 | XMD400/800 | |

| Drive power | kw | 7.5 | 15 | 22 | 22 | 30 |

| Rotor diameter | mm | 300 | 300 | 300 | 400 | 400 |

| Rotor width | mm | 300 | 585 | 785 | 600 | 800 |

| Number knife | 3*1 | 3*2 | 3*2 | 3*2 | 3*2 | |

| Number knife | 2*1 | 2*1 | 2*2 | 3*1 | 3*2 | |

| Size | mm | 400*350 | 580*390 | 780*390 | 540*585 | 550*780 |

| Crushing cavity diameter | mm | 370*300 | 370*585 | 370*785 | 490*600 | 490*800 |

| Weight | kg | 700 | 1100 | 1150 | 1700 | 2100 |

| Screen aperture | mm | 10 | 10 | 10 | 10 | 10 |

| Dimensions | L*W*H mm | 1350*800*1800 | 1400*1100*1900 | 1400*1300*1900 | 1700*1350*2250 | 2100*1550*2500 |

| Model | XMD400/1000 | XMD500/800 | XMD500/1000 | XMD500/1200 | XMD600/800 | XMD600/1100 | XMD800/1200 | |

| Drive power | kw | 37 | 37 | 45 | 55 | 45 | 75 | 90 |

| Rotor diameter | mm | 400 | 500 | 500 | 500 | 600 | 600 | 800 |

| Rotor width | mm | 1000 | 800 | 1000 | 1200 | 800 | 1100 | 1200 |

| Number knife | 3*2 | 5*2 | 5*2 | 10 | 5*2 | 5*2 | 5*2/7*2 | |

| Number knife | 3*2 | 3*2 | 3*2 | 6 | 3*2 | 3*2 | 3*2 | |

| Size | mm | 550*980 | 650*780 | 650*980 | 960*1190 | 790*780 | 790*1080 | 1140*1170 |

| Crushing cavity diameter | mm | 490*1000 | 600*800 | 690*1000 | 590*1200 | 740*800 | 740*1100 | 950*1200 |

| Weight | kg | 3200 | 3150 | 4200 | 5000 | 4500 | 5500 | 7000 |

| Screen aperture | mm | 10 | 12 | 12 | 12 | 12 | 12 | 12 |

| Dimensions | L*W*H mm | 2100*1800*2500 | 2300*1800*2900 | 2300*2000*2900 | 2800*2200*3450 | 2600*1800*3300 | 2600*2200*3300 | 3100*2450*4100 |

Keyword:

Next page:Soundproof type crusher (XMC series)

Previous page:Series pipe & profiles crusher (XMP series)